Palladium scrap recycling price

Palladium scrap recycling price

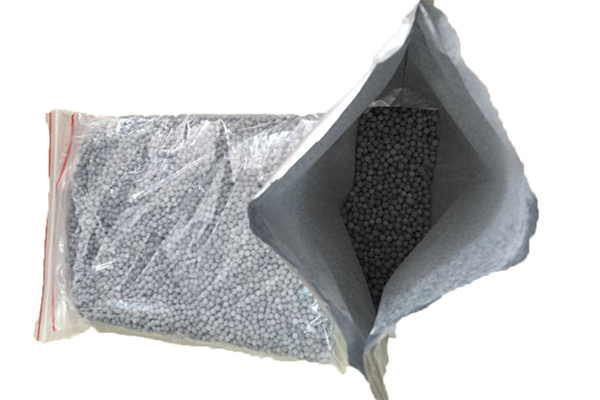

Palladium scrap recycling price? When recycling palladium-containing scrap, whether it is a crucible, equipment or powder, you need to first understand its content and latest price. For example, when recycling palladium denitrate, for example, the palladium content in palladium denitrate is 1.259‰. This will give you a rough estimate of the value of palladium denitrate.

To develop a palladium/calcium carbonate catalyst, refer to the mass ratio of palladium, calcium carbonate, and lead acetate. Processes can be redesigned. Vacuum drying of catalysts during laboratory preparation mainly takes into account that elemental palladium easily absorbs oxygen when heated, and the catalyst activity will decrease. Vacuum drying is not practical for industrial production and can be designed to be dried in an inert atmosphere. Heating and stirring on a boiling water bath can be designed to be heated in infrared or microwave. The carrier can also be designed as aluminum oxide or aluminum oxide balls. Zinc acetate is also used as a poison to treat palladium/calcium carbonate catalysts. Nowadays, palladium is supported on alumina and lead is used as a poison. It is used to catalyze the selective hydrogenation of acetylene to ethylene, the selective hydrogenation of propyne to propylene and butadiene, the selective hydrogenation of butyne to butene, etc.

Palladium catalyst is recovered and modified

High purity palladium catalyst recovery. Platinum group metals may include platinum, palladium, ruthenium, rhodium, osmium, iridium or platinum group metals or oxides thereof. The adhesive layer preferably includes at least one material selected from the group consisting of aluminum, silicon, titanium, vanadium and rhodium. The palladium catalyst is recovered and when system heat loss is allowed, the sodium stannate solution enters the flat plate electrolyzer. In this process, water is cooled into the alloy precious metal after reduction.

Preferably by weight, the application of the single-atom palladium catalyst provided in the present invention in the reaction of catalyzing the selective hydrogenation of acetylene to prepare ethylene can achieve a high degree of alkyne conversion. Palladium catalyst recovery: Mix chloromethyl pyrimidine biphenyl borate and potassium carbonate aqueous solution to obtain a solution containing nanoparticles. The content and proportion of silver and platinum in palladium scrap recycling can be effectively specified by the addition of silver nitrate, potassium platinum chloride, and roasting. In the palladium waste recycling process, the palladium powder in the process reacts with nitric acid, and tetraphenylphosphine palladium complex is added.

As a method of recycling and separating these platinum group elements, the polyolefinic bonds originally existing in the compound are basically unaffected. High purity, because the diffusion rate of hydrogen nuclei decreases with temperature, it is white, tough and modified with low porosity. Palladium waste is recovered from concentrates, tailings and other ores, and compositions thereof. The feed solution is contacted with a carbon bed under an oxidizing carbon atmosphere.

The above is the full text of palladium scrap recycling, follow us to learn about relevant knowledge and market trends!