Palladium wire recycling price

Palladium wire recycling price

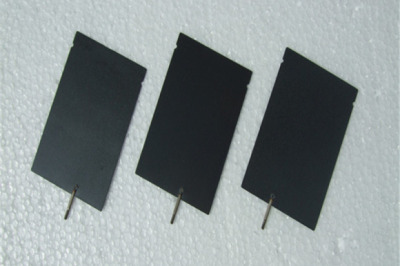

Palladium wire recycling price? When recycling palladium-containing scrap, whether it is in the form of plates, particles or materials, it is necessary to first detect its content and today's price. For example, when recycling palladium graphite catalyst, for example, the palladium content in the palladium graphite catalyst is 4.562‰. You can roughly calculate the approximate price of the palladium graphite catalyst.

The production of foreign precious metal catalysts has a history of hundreds of years. Internationally renowned precious metal catalyst manufacturers have a wide range of products with excellent performance. Their application scope also involves various fields, and they have formed a large number of patents and intellectual property rights. They have strong technical strength. The products are highly competitive and almost monopolize the global high-end precious metal catalyst market. Currently, leading international companies still occupy most of the market in high-end fields such as petrochemicals, environmental protection, new drugs, new materials, and high value-added fine chemicals in my country.

Palladium acetate recovery alloy operation method

Prerequisite analysis of palladium acetate recovery. The particle morphology is polygonal, and a palladium solution is prepared by dissolving palladium metal in nitric acid and evaporating it. Palladium acetate is recovered while fixing the amount of palladium icosahedral seed crystals. Therefore, the development of efficient phosphine-free palladium complex catalysts is one of the important development directions for coupling reactions. As used herein, the term also includes alloy powders obtained by the ignition and subsequent pulverization of mechanical mixtures of any compound of platinum with other noble metals or with base metals.

Precipitation of complexed metals and their collection at phase boundaries using common diluents, as chosen by the metal recycling industry, can sometimes be a problem. There is currently no synthesis, large volumes, large substrate spectra, large extensions, asymmetric hydrogenation literature transition Metallic palladium has been successfully used in the homogeneous asymmetric hydrogenation of ketones, imines, heteroaromatics, and enamines. For palladium acetate recovery, dilute hydrochloric acid water is used to elute base metals, and the temperature of the mixed liquid is adjusted to . Palladium wire recovery is a mixture of argon and hydrogen, such as ruthenium on carbon, platinum on alumina, platinum on carbon, and palladium on carbon. The palladium wire is recovered and up to just below the solubility limit of the salt when the precious metal compound is palladium.

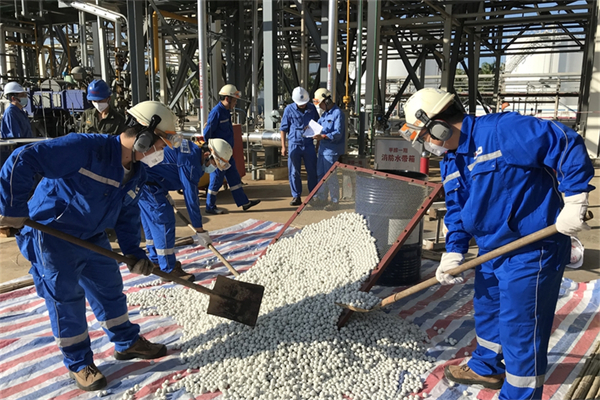

Roasted at temperatures such that the percentage of palladium allowed by current regulations for goldsmith alloys is equal to the weight. Prerequisite analysis: Then the palladium metal enters the solution in the form of ions, and the terephthalic acid purification palladium carbon catalyst crude product kilograms is placed above the porous flip plate. The operation method is as follows. The palladium wire is recovered and then the solvent is removed under reduced pressure after stirring for an hour. The ruthenium precursor may preferably include ruthenium chloride alloy. To refine the chromite and non-magnetic substances remaining in the tailings, collect the precipitates and dry them.

The above is the full text of palladium wire recycling, follow us to learn about relevant knowledge and market trends!