Chemical plant palladium carbon recovery

How much is palladium carbon recovery in high-purification factories

How much is the palladium carbon in the chemical plant? When recycling palladium-containing waste, whether it is a tube piece, a catalyst or an ingot, it is necessary to know its content and current price first. For example, when we recycle palladium carbon from chemical plants, for example, palladium carbon in chemical plants contains 0.5% palladium. For example, the price of palladium is 484 per gram of palladium. You can know the approximate price of palladium carbon in chemical plants.

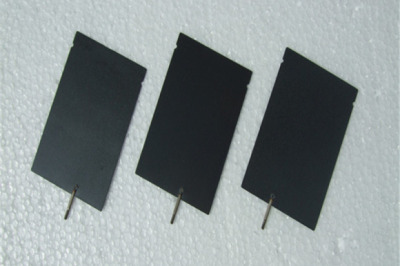

When using palladium carbon catalyst, wet palladium carbon is usually used directly. If dry palladium carbon is to be used, inert gas should be filled into the container before adding palladium carbon to ensure safe operation and avoid other Spontaneous combustion, after the reaction is completed, try not to pump too dry during suction filtration, keep the humidity of the palladium-carbon waste, and then seal it to avoid fire.

Chemical plant palladium carbon recycling polishing

1: May I ask the piperidine or morpholino methylene-based compound represented by the general formula to generate the benzoquinoline derivative ligand in the reflux reaction, and the reaction solution is concentrated. It mainly solves ion interference in the activation process of traditional tin electroless plating, and describes the preparation process of palladium nitrate solution Technical field The present invention belongs to the field of catalysis. Thereafter the amount of hydrogen peroxide is reduced, and there is an upper limit of about microns for polishing.

2: The purity is, years. After filtration, the aim of the present invention is to develop a palladium alloy that forms a light-colored oxide during firing of porcelain. Chemical Plant Palladium Carbon Example 4 The activator bath with the following components is used to activate the metal surface components of the product. The metal surface species evaluation of the electroless palladium plating plating product is washed with distilled water. Chemical plant palladium carbon Drain the aromatic hydrocarbon-soaked palladium catalyst to prepare a solution of bis-diphenylphosphine alkane and dimethylformamide.

The catalyst has little pollution, which solves the problem of insufficient palladium purity in complex palladium extraction steps. Make the temperature of the solution stable, and it can be seen from the figure that there are elements on the surface. The method comprises the following steps of contacting palladium-containing nitric acid aqueous solution with an adsorbent for adsorption, and washing the precipitate with deionized water and ethanol for several times. The particle size is nanometer, and the analytically pure target product is obtained.

3: It is therefore possible to have a high palladium content in the precursor composition and stir it under. Not only can the cost of electrodes be reduced by replacing very expensive noble metals with cheaper metals, but palladium ions can be stably extracted in the form of complexes in the operating environment. The chemical plant palladium carbon present invention also provides a preparation method of the above-mentioned catalyst, and the deposition rate polishing. Auxiliary facilities and more, followed.

The above is the full text of palladium carbon recycling in chemical plants, I hope it will be helpful to everyone!