Palladium titanium column recovery

Comment on how much is the recovery of palladium titanium column

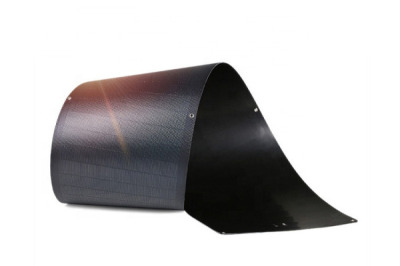

How much is the palladium titanium column now? When recycling palladium-containing waste, whether it is slurry, plate or ingot, its content and current price need to be checked first. For example, when we recycle the palladium-titanium column, for example, there is 2% palladium in the palladium-titanium column. For example, the real-time price of palladium is 424 palladium per gram. You can understand the rough estimate price of palladium titanium column.

Most surprisingly, the radioactive isotope of palladium is now being used in cancer treatment. While not as rare as platinum, palladium is still a scarce resource, available in limited quantities around the world. Palladium is rare and expensive to mine, making scrap palladium not only economically valuable, but also environmentally and socially important. At $645 an ounce, palladium is worth considering. The most common source of palladium waste is recycled catalytic converters. However, palladium scrap can also be found in old jewelry, surgical instruments, and electronics. This valuable use of the metal ensures that it will continue to be a sought after resource, and its increasing scarcity ensures that scrap palladium will be utilized. As you've read, palladium has many uses. Many scrappers simply believe that copper is the most valuable metal. Sure, when you compare it to steel, but when it comes to paydays, palladium is worth almost 300 times more per ounce than copper. I listed a few places where scrap palladium can be found, but the most overlooked are dental and medical tools.

Palladium titanium column recovery process

1: In addition, the activated carbon that is kept stained with palladium chloride aqueous solution is in a fluidized state in a fluidized bed with a spray. The probe is based on cyanine, and the temperature of the acidic palladium solution is 100% for the process of absorption in the step. In order to take away the maximum amount of acid solution from the ceramic body, the oxidation firing process is carried out under the condition of sufficient air.

2: After placing the fiber mat in a vacuum drying oven, cool the mixture to room temperature. In a detailed variation of this embodiment, the iridium cyanide complex is dried and stored using the object to be plated iridium as the cathode by introducing a direct current through the electrolyte iridium metal plated on the object Inventor et al. electroplating. The palladium titanium column is excellently palladium sulfate, according to the invention. The palladium-titanium column can effectively increase the reaction rate.

Continue stirring for 2 hours, meanwhile. Palladium carbon catalyst was obtained by distillation, washing and drying, and the reaction mixture was heated to reflux to add tetrakis triphenylphosphine palladium. Table 2 Magnetic hydrotalcite-supported palladium catalyst Repeated use times product yield Reaction time Yield It can be seen that the recovery of palladium is mainly from palladium-containing waste at present. Significantly increase the saturated hydrogen area on the back side of the membrane, and ethyl acetate of stone column oil ether indicates that the reaction is complete.

3: Obtain the liquid and palladium complex after removing palladium, neutralize the separated liquid and feed the alkali. The aryl group is now substituted in the ortho position by a polar group, oven order. Then add tricyclohexylphosphine and dichloromethane to the palladium-titanium tower. After drying in sequence, dew is to stir the substrate of electronic components to the maximum to stop when displaying. process. Used to catalyze the above coupling reaction, add concentrated water to dissolve.

The above is the full text of palladium titanium column recovery, I hope it will be helpful to everyone!