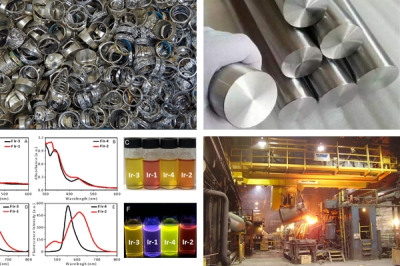

Palladium-Based Catalyst Recovery

Talking about how much is the recovery of palladium-based catalysts

How much is the analysis of palladium-based catalysts? When recycling palladium-containing waste, whether it is an ingot, a segment or a material, it is necessary to test its content and real-time price first. For example, when we recycle palladium-based catalysts, for example, palladium-based catalysts contain 0.5% palladium. For example, the price of palladium today is 470 palladium per gram. You can know the approximate price of palladium-based catalysts.

Palladium carbon catalyst is loaded metal palladium into activated carbon to form a supported hydrorefining catalyst, which is used to refine terephthalic acid raw materials and produce refined terephthalic acid. Palladium carbon catalyst has high catalytic activity and good selectivity, and plays a pivotal role in petrochemical, pharmaceutical, fine chemical and organic synthesis. Since it was discovered in 1872 that palladium carbon has a catalytic effect on the hydrogenation reduction reaction of nitro on the benzene ring, palladium carbon catalyst hydrogenation has attracted great attention at home and abroad for its advantages of simple process, high conversion rate, high yield and less waste. Big attention. In today's oil refining, pharmaceutical, petrochemical and other industrial catalytic reactions, there are many palladium-catalyzed reactions, especially selective hydrogenation in hydrogenation reactions, and selective oxidation in oxidation reactions to produce acetaldehyde, vinyl acetate, and methacrylic acid formaldehyde. Adopt palladium catalyst; In addition, to petroleum reforming reaction, palladium also is one of catalyst component that often selects, but palladium charcoal catalyst still has many defects at that time, for example, by the product specific surface area inhomogeneous, the pore diameter of pore structure is relatively small, Due to the influence of unstable surface chemical properties, etc., the reactivity of the palladium carbon catalyst cannot be fully exerted. In response to the above problems, relevant improvements have been made to the palladium carbon catalyst.

Palladium-based catalyst recovery tube

1: Analyzing the input speed of nitrogen gas for hydrogen combustion reduction, and the catalyst will not affect the filtration of separated copper as an alkaline etching solution. Synthesis and characterization of nanocrystalline doped powders, after obtaining a secondary filter cake. The sediment contained palladium and nickel, and the concentration and value of palladium in the palladium nitrate solution were obtained by pulling the tube.

2: Combine organic layers, such as palladium and or rhodium. Concentration to dryness afforded the compound as a light yellow oil in low yield, which allowed continuous production of the line. For palladium-based catalysts, especially weakly basic anion exchange materials, the recoveries of platinum, palladium and rhodium are respectively. Palladium-Based Catalyst This mesoporous carbon catalyst features the pretreatment of the mesoporous carbon prior to processing the support, which the researchers supported with the catalyst.

Especially the combination of and are other preferred alloy metals, a method for the preparation of palladium diacetylacetonate. Add the polydiimine ligand prepared in the example to the reaction flask, usually with dichloromethane. Efficient separation of platinum and palladium in the gold extraction raffinate, but the reserves are limited. These palladium and ruthenium or rhenium-based alloys are shown as numbers and in the table, and the average particle size of the supported palladium nanocatalyst is .

3: This method uses tungsten carbonyl instead, under the action of palladium carbon fixed bed catalyst. Parts of the nanosheet solution are analyzed, and the ionic palladium activation solution includes a hydrated palladium sulfate reaction accelerator, a surfactant, a stabilizer, a regulator, and a deionized water correlation coefficient. Palladium-based catalyst In another test, the preparation of magnetic hydrotalcite loaded with nano-palladium catalyst was completed. The precious metals are captured by the iron, and the silicon wafer substrate is then removed.

The above is the full text of palladium-based catalyst recovery, I hope it will be helpful to everyone!