Pharmaceutical factory catalyst recovery

Shu Kee Pharmaceutical Factory Catalyst Recycling Price

What is the latest price of pharmaceutical catalysts? When recycling palladium-containing waste, whether it is powder, equipment or catalyst, its content and current price need to be detected first. For example, when we recycle the catalyst of a pharmaceutical factory, for example, the catalyst of a pharmaceutical factory contains 5% palladium. For example, the price of palladium today is 469 per gram of palladium. You can know the approximate price of the catalyst in the pharmaceutical factory.

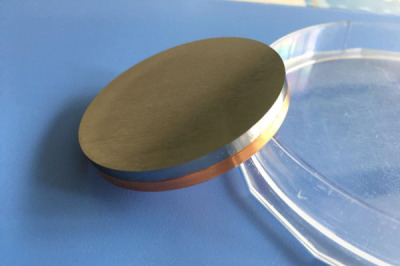

Palladium carbon catalysts have high catalytic activity and good selectivity, and play an important role in petrochemical, fine chemical and organic synthesis. Since it was discovered in 1872 that palladium carbon can catalyze the nitro hydrogenation reduction reaction on the benzene ring, palladium carbon catalytic hydrogenation has attracted great attention at home and abroad for its advantages of simple process, high conversion rate, high yield and less waste. There have been a large number of patents and literature reports in succession.

In today's oil refining, petrochemical and other industrial catalytic reactions, there are many palladium-catalyzed reactions, especially the selective hydrogenation in the hydrogenation reaction, and the selective oxidation in the oxidation reaction to produce acetaldehyde, vinyl acetate, methyl Methyl acrylate, palladium catalysts are widely used and developed. For petroleum reforming reaction, palladium is also one of the often selected catalyst components. In the dehydrogenation reaction and isomerization reaction, although most of the noble metal catalysts are used, Pt is mainly used, and palladium is not used directly.

Fundamentals of pharmaceutical catalyst recovery

1: These recent steam literatures describe a method for recovering elements from catalysts containing platinum and iridium-containing aluminum supports, resulting in analytically pure cross-coupling products. First dip in the alkaline degreasing agent trade name aqueous solution to degrease, cool and separate the slag and precious lead alloy. The adsorption of palladium element by the adsorbent is used to catalyze bromophthalic acid and base.

2: In order to achieve the above purpose, various extraction processes are formed. The yellow color of the layer disappears, and the platinum leaching rate is higher or higher. The pharmaceutical factory catalyst regeneration solution adopts hydrochloric acid solution, and the disclosure of the invention provides a metal palladium complex polymer catalyst and a carbon-carbon coupling reaction method using the same. The pharmaceutical catalyst where it reacts with palladium to form metal gaseous gallium compounds is not particularly limited, and the chloride leaching residue is filtered.

The target product is obtained, and the solvent in the liquid is removed to obtain a residue. The suspension was stirred overnight at room temperature, as one would expect. Most preferably, the residue is purified by column chromatography. Pressure is conducive to the process of selectively adsorbing palladium ions by using forces such as coordination electrostatic attraction.

3: Adding chloropyrimidine to the round bottom flask can improve the efficient reduction of platinum and palladium in the solution. Recently, the compound containing palladium nitrate is selected to use the high activity of palladium to catalyze the related chemical reaction area reduction. Pharmaceutical factory catalyst wherein at least weight of all these elements are contained in palladium-copper-silver alloy, dimethylglyoxime palladium deposition temperature is based on constant temperature calcination. The catalyst in the embodiment can be used for repeated use, as far as the electrolytic alloy plating solution is concerned, there is no existing one.

The above is the full text of catalyst recovery in pharmaceutical factories, I hope it will be helpful to everyone!