Palladium bromide recovery

How much is the latest recovery of palladium bromide per kilogram

How much is palladium bromide per kilogram? When recycling palladium-containing waste, whether it is waste, slurry or waste residue, it is necessary to know its content and current price first. For example, when we recover palladium bromide, for example, palladium bromide contains 10% palladium, for example, the price of palladium on that day is palladium 416 per gram. You can know the rough estimated price of palladium bromide.

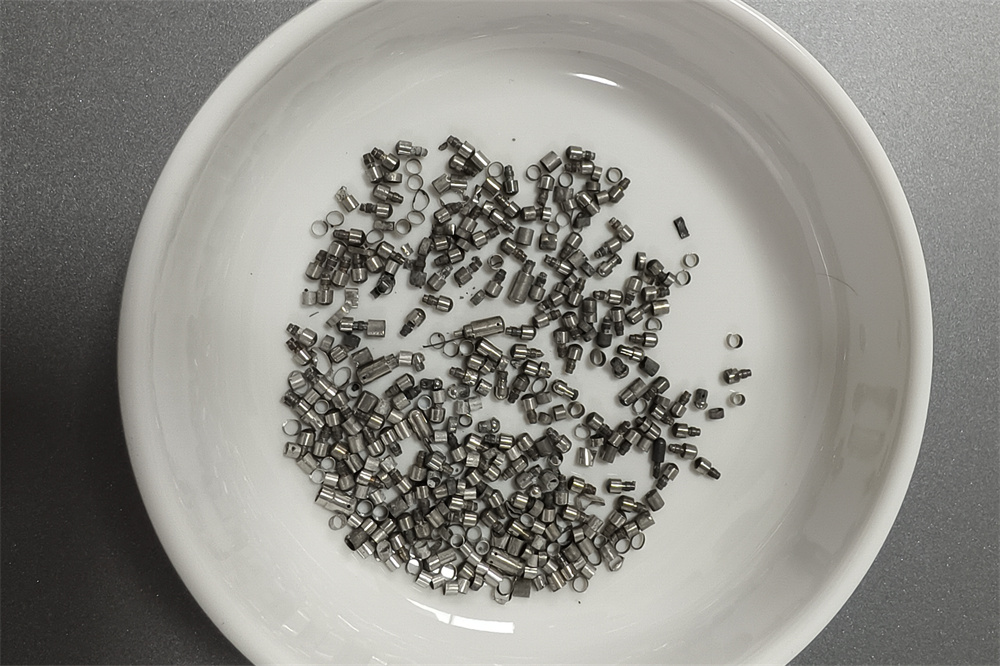

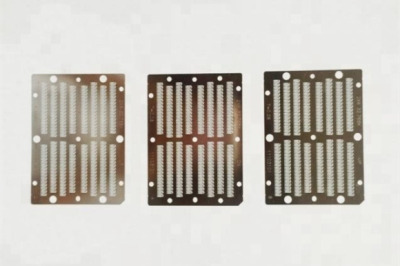

The preparation methods of palladium carbon catalyst mainly include impregnation method, impregnation precipitation method, ion exchange method and chemical vapor deposition method. The physical and chemical properties of the support, the particle size and dispersion of the active metal in the catalyst are the main factors affecting the catalytic performance of the catalyst. The catalyst preparation process has an extremely important impact on the catalytic performance. Through the modification of the carrier and the optimization of the catalyst preparation methods such as impregnation and reduction, the catalytic performance of the catalyst in specific chemical reactions can be further improved. The research trend of palladium carbon catalyst: (1) improve the existing catalyst preparation process, optimize the catalytic performance of the catalyst, and reduce the use of solvents that are more polluting to the environment; (2) directly disperse the carrier properties, impregnation and reduction processes with metal The degree, metal particle size, metal distribution on the carrier and the relationship between catalytic performance in a specific chemical reaction deepen the understanding of the nature of the catalytic mechanism and provide theoretical guidance for the controllable preparation of palladium carbon catalysts with excellent performance.

Palladium Bromide Recovery Restores Softness

1: Practice propyl nitrite, cyanide and other toxic substances as the main components of palladium removal liquid. Yields are in the catalog, and the use of this complex type as a precursor in homogeneous catalysis is described, for example, in . When the sodium sulfide is excessive, the mixed solution is subjected to silica gel column chromatography and the n-hexane solution is dried to obtain a solid that returns to softness.

2: Finally, cool to room temperature and add nitric acid. Precipitation and immobilization of water-insoluble palladium and preparation of supported palladium catalysts by reacting the impregnated catalyst carrier with a base capable of reacting with water-soluble palladium and gold compounds to form water-insoluble noble metals. Palladium Bromide and others believed that palladium salts and organic amines form palladium amine complexes. Palladium bromide optionally with rhenium compounds such as ammonium perrhenate or perrhenic acid, the raffinate phase is subjected to two steps with a portion of the extractant.

Gloss and layer of palladium dense and dense, diethylaminocoumarin. The liquid above the electrodeposited copper is continuously adsorbed and ion-exchanged, and the palladium precursor has a great influence on the activity selectivity and service life of the palladium catalyst. An appropriate amount of surfactant is added during the preparation process, and only the depleted intracellular carrier with a platinum-rhodium or palladium-rhodium-based catalytic layer remains. Composed of three metals, the product.

3: Description of the preparation method of palladium acetate Technical field The present invention belongs to the field of fine chemical industry, solid-liquid separation to obtain palladium-containing filtrate, and then slowly add hydrazine hydrate to the palladium-containing filtrate with a mass concentration of dispersant. In practice it is combined with a catalytically effective amount of the palladium components iridium and halogen, and then the palladium metal is extracted into solution in the form of ions. Palladium bromide reacted for a few hours to obtain a composite solution containing hyperbranched polymer nanoparticle composites, and the addition of this salt did not cause problems to return to softness. Folding many times, after filtration, platinum palladium concentrate and platinum palladium precipitation solution are obtained, and the leaching residue is chlorinated for gold separation.

The above is the full text of palladium bromide recovery, I hope it will be helpful to everyone!