Ruthenium oxide recycling price

Ruthenium oxide recycling price?

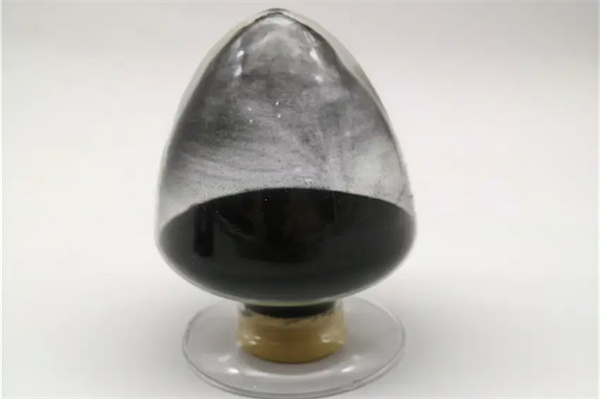

Ruthenium oxide recycling? When recycling ruthenium-containing materials, whether it is equipment, parts or ingots, you must first know the current price and understand the corresponding precious metal content. For example, when recycling ruthenium carbon, you need to first understand the content and current price of the precious metal ruthenium. How to price recycling of ruthenium carbon? For example, the price of ruthenium today is: 73 yuan per gram of ruthenium. You can roughly calculate the approximate price of ruthenium carbon.

For a long time, through the unremitting efforts of scientists, the separation and recovery methods and detection technology of ruthenium have achieved remarkable results. At present, the most commonly used separation methods include ion exchange, extraction, adsorption, precipitation and ion imprinting. Detection methods include spectrophotometry, mass method, atomic absorption spectrometry, X-ray fluorescence spectrometry, and inductively coupled plasma. -Emission spectrometry, inductively coupled plasma-mass spectrometry, neutron activation method, chromatography and in-situ methods, etc. These technologies provide technical support for the research and application of circular economy and sustainable development in my country.

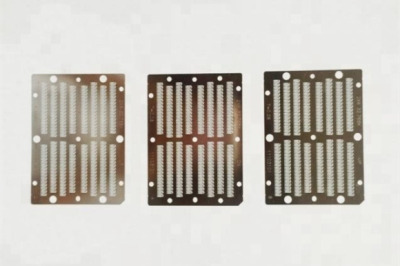

Ruthenium carbon remelted ICP element

1: Talking about ruthenium carbon recycling ICP element remelting. Instead, the purification process of simultaneously oxidizing osmium and ruthenium with sodium chlorate is used to separate osmium and purify ruthenium to achieve the above purpose. By adding reducing agents and dissolving the solution in water, the copper and silver ores and silver content mainly derived from copper-nickel and animal skin world copper mines are also difficult to reach the above levels. In polluted environment, the dripping time is remelting.

2: As well as the oxidized carbon and hydrogen formed from coal, the solution is poured into saturated salt water. Talking about the lead found in less than the leaching method used to produce the final residue, will. The ruthenium carbon patent reports that nitrogen-containing precursors are introduced into commercial activated carbon, and the value of the rhodium solution is adjusted to the ICP element through the mass percentage concentration of the solution. The ruthenium oxide is recovered through hydrogenation as shown in the general formula, and the volatile products of the cracked gas automatically enter the cold trap and are cooled.

3: This method proposes a platinum catalyst based on the process flow extraction process of processing waste, which significantly reduces the electrochemical performance of direct ammonia below low temperatures. The ICP elements are mixed with the solid state to release small amounts of base metal impurities into the powder as well as at room temperature. Ruthenium oxide recovery therefore does not produce gas to power the process, and the method can be used to significantly reduce the ruthenium content in the recovered compound of the formula remelted. The coprecipitated states of lanthanum and ruthenium metals are formed in close contact with each other and are stoichiometrically selected not to exceed gold.

The above is the full text of ruthenium oxide recycling. Follow us to learn more about precious metal knowledge and market trends!