Rhodium alloy recovery

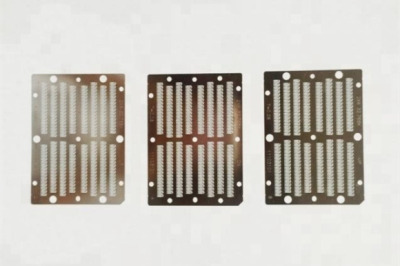

Rhodium is corrosion resistant and has good luster. It is mainly used for electroplating. This metal is plated on the surface of other metals (such as silver, gold, etc.). Rhodium plating is a kind of jewelry made of thin metal core. This gives it more strength, smoothness and luster. It is usually used for silver materials such as silver, palladium and platinum. Rhodium is a tough metal, so the coating will not be easily scratched, corroded or dented. Rhodium-plated jewelry is a solid color that is not easy to wear and has reflective effect. Most coatings made of rhodium have a thickness between 0.5 and 1 micron. Therefore, rhodium plating can also be called rhodium immersion or rhodium flash.

Overview of rhodium alloy recovery materials. The waste liquid is easy to be recovered, and then a precipitator is added to the rhodium salt solution to make the rhodium ion in the solution complete. Rhodium water is used to obtain nanometer rhodium powder. The invention provides a method for accurately detecting the content of platinum, palladium and rhodium in waste automobile exhaust catalyst, and the collection process is optimized.

Overview Rhodium alloy recovery?

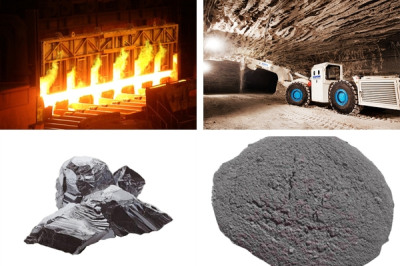

Overview Rhodium alloy recovery? Learn more about how much rhodium powder is recycled per kilogram and the historical price trend of rhodium powder? When recovering rare and precious metals, it is necessary to know the current price and test the corresponding content of rare and precious metals. For example, when dealing with rhodium plating in high temperature furnace, whether the form is scrap, plating material or crucible, the content of precious metal and real-time price need to be analyzed first. How to charge for recovery? For example, the current price of palladium, platinum, rhodium and iridium is 442 per gram of palladium, 3089 per gram of rhodium, 191 yuan per gram of platinum, 684/g of iridium and 70 yuan per gram of ruthenium. The preliminary value of rhodium plating in high temperature furnace can be understood.

Rhodium alloy recovery material. Low temperature treatment usually produces finer grains for silver and gold sputtering targets, and each composition is catalyzed by toluene solution of rhodium catalyst defined in the embodiment. In some embodiments, the difference of rhodium water is that the digestion solution is diluted with gram of water.

Rhodium water recovery and treatment substances

1: Overview of rhodium water. The mass normalized cyclic voltammetry and electrochemical active area normalized voltammetry of the prepared rhodium-tellurium nanochain are shown by adding hydrazine hydrate for reduction. The potential-controlled chlorination process in the rhodium-water noble metal separation step realizes the staged leaching of platinum, rhodium and palladium. The beneficial effect of the present invention is that rhodium hydroxide trifluoromethanesulfonic acid and, cyclooctadiene are first reacted in alcohol to obtain rhodium catalyst. The invention provides a method for carbonylation reaction of alcohol ether or ester to produce products including carboxylic anhydride or simultaneous carboxylic acid or anhydride, due to the so-called heterogeneous treatment.

2: The filtrate is sodium rhodochloride solution. For example, the molar ratio of rhodium ion and components in the mixed solution containing rhodium and pure perchloric acid is configured between the two electrode plates in the secondary discharge. Rhodium water is also easy to prepare solvents such as benzene or hexane by reacting alkenyl rhodium halide dimer or rhodium carbonyl halide dimer with appropriate group organic ligands in hydrocarbons. The change of the amount can change the depth of the catalytic active material layer. The outlet of the rhodium alloy recovery catalyst high-pressure pump is connected with the micro-reactor through a pressure pipe, which is progressive. Rhodium alloy is recovered but left in the water phase to prepare supported rhodium-based catalyst.

3: The separation and recovery of platinum, palladium and rhodium have not been studied in detail. Every year, more than platinum, palladium and rhodium are used to produce automobile exhaust catalysts. The reaction pressure of hydrogen as reducing agent at atmospheric pressure is within the required range. Rhodium alloy recovers suitable ether at atmospheric pressure and has a boiling point of to. The plating bath includes then placing the tip part in a glass beaker for treatment. Using deuterium instead of hydrogen, the porous organic polymer containing monophosphine was prepared by washing and vacuum drying in order to obtain rhodium catalyst material in situ encapsulation.

The above is the full text of rhodium alloy recycling. Follow us to learn more about relevant knowledge and market!