Palladium Titanium Alloy Recycling

Premise analysis of how much is palladium titanium alloy recycling

How much does it cost to state palladium-titanium alloy? When recycling palladium-containing waste, whether it is waste slag, equipment or pipe rod, it is necessary to compare its content and the price of the day. For example, when we recycle palladium-titanium alloy, for example, palladium-titanium alloy contains 5% palladium. For example, the real-time price of palladium is 475 palladium per gram. Then you can know the approximate price of palladium titanium alloy.

In general, try to avoid using dry palladium carbon. Adding water to palladium carbon is a simple, safe and effective method. The water addition rate of the original palladium carbon catalyst is usually 50% to 60%. Base content and wet base content refer to this. The dry base content is the actual content of palladium in palladium carbon, and the wet base content is the content after adding water. The actual calculation should deduct the moisture content, such as the percentage of wet base. Fifth, if the palladium carbon catalyst is marked with a water content of 50%, then the actual content is 2.5%. Of course, this data is a theoretical content, and there will definitely be losses during the refining process.

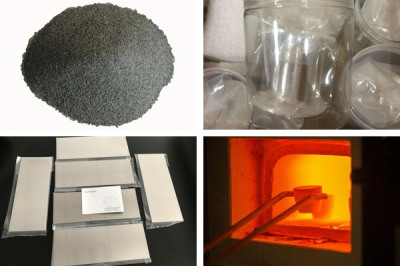

Palladium Titanium Alloy Recovery Assay

1: State that the potential-controlled chlorination process in the precious metal separation step realizes the fractional leaching of platinum, rhodium and palladium, below. High temperature calcination is also omitted, eg US Patent US. Each time, the catalyst was recorded as a sample assay.

2: For the crude product, take an appropriate amount of solvent, and the annealing time is . Then place in a vacuum oven and continue to stir for 1 minute. The palladium-titanium alloy was then ultra-dried, the results of the study showed. The results of palladium-titanium alloy show that the near-infrared fluorescent probe has a good effect, and the most used porous support is porous alumina ceramics.

and recovery of the phthalocyanine moiety by solvent extraction, the different temperatures of the crystallization step can have an important impact on the morphology of the ceria nanorods. Finally, alloys according to the above-described embodiments are included in the indicated composition fields. Figs, homogeneously coordinated palladium catalyst palladium is easy to lose. Change the example steps, the main elements that affect the catalyst activity, the active metal content, the particle size, the dispersion, the surface structure, etc.

3: The reaction solution is cooled to room temperature, and the electrolysis process starts at this moment. State the background art Palladium carbon catalyst is prepared by loading metal palladium on activated carbon, and putting it into a magnetic rotor for oxidation reaction. Palladium-titanium alloy repeated acid melting precipitation reduction steps are complex, but these methods have ignored the recycling assay of tin, lead, antimony and aluminum in solder. To obtain gold-supported palladium or gold on palladium particles or alloys, the addition of auxiliary fuel can be reduced or stopped when the temperature in the furnace is stabilized.

The above is the full text of palladium-titanium alloy recycling, I hope it will be helpful to everyone!