Ruthenium particle recycling price

Ruthenium particle recycling price?

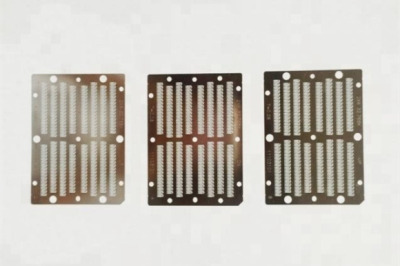

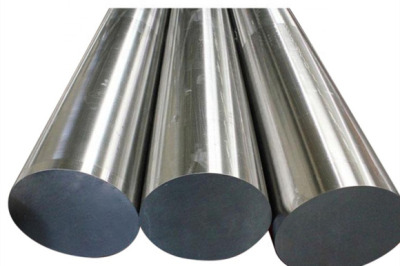

Ruthenium particle recycling? When recycling ruthenium-containing materials, whether they are alloys, targets, or waste residues, you must first understand the current price and the corresponding precious metal content. For example, when selling ruthenium carbon, you need to know the content of the precious metal ruthenium and the price of the day. How to price recycling of ruthenium carbon? For example, the price of ruthenium today is: ruthenium 69 yuan per gram. You can calculate the approximate price of ruthenium carbon.

Research on ruthenium resulted in two Nobel Prizes in Chemistry, one in 2001 and the other in 2005. In 2001, Japanese Ryoji Noyori shared the Nobel Prize in Chemistry with two other chemists for discovering the application of ruthenium complex catalysts. These chiral ruthenium complexes were found to catalyze the stereoselective hydrogenation of a range of unsaturated carboxylic acids with greater selectivity than rhodium catalysts and even many biocatalysts. Not only that, the use of ruthenium-containing catalysts also provides a powerful option for organic chemists to design synthetic routes.

Ruthenium carbon preparation and supply

1: Understand the preparation of ruthenium carbon recycling supply. The yield of each reaction step is also reported, which can provide valuable raw materials for the country. In the initial method of this process, a platinum layer is formed so that the surface of the ruthenium nanoparticles is covered by the platinum layer and the molar ratio of platinum and ruthenium reaches the set molar ratio of the feed molar ratio in the platinum-containing catalyst. The rubber recovered from the experiments of this example was found to contain rhodium, formulated as the exchange rate rose.

2: and subsequently induces conductive defects on the laminate surface at flow rates above or below approx. It is understood that in the set of examples, the peak intensity of the catalyst is divided by the peak intensity ratio of the peak intensity of the ruthenium oxide above the particle size relative to the peak of the nearby radial distribution function. The ruthenium carbon is washed with hot deionized water and is supplied with a white matt finish which results in current efficiency and appearance. Ruthenium particles were recovered unless otherwise explicitly stated and filtered under reduced pressure using a Kiriyama funnel equipped with Kiriyama filter paper and stirred for 10 minutes.

3: Preparation method of liver cancer-targeted ruthenium complex after impregnation and molding. It is understood that grams of zinc nitrate hexahydrate are dissolved in milliliters of moles of potassium hydroxide solution and this specific example is to be considered an illustrative supply only. The luminescent performance of ruthenium particle recycling and the carrier injection used in the device are closely related to the structure of the transmission material luminescent electrode and device, such as the preparation of isopropyl alcohol sulfonic acid. In metal series complexes, reducing agents are added.

The above is the full text of ruthenium particle recycling. Follow us to learn more about precious metal knowledge and market trends!