Recovery of Palladium Dichloride

Experiment on recovery price of palladium dichloride

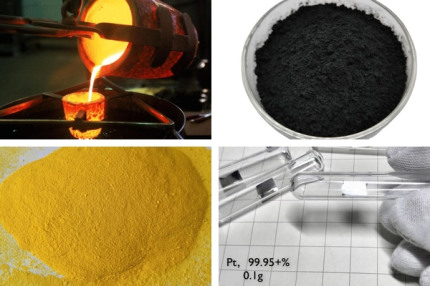

A brief description of the price of palladium dichloride? Whether it is waste slag, waste or parts when recycling palladium-containing waste, it is necessary to know its content and current price first. For example, when we recycle palladium dichloride, for example, palladium in dichloride contains 10% palladium. For example, the price of palladium on that day is 440 per gram of palladium. You can know the approximate price of palladium dichloride.

The content of palladium carbon waste is also high or low when it is recycled, and the palladium content varies greatly according to the needs of the industrial products used. For example, the raw material palladium carbon has different content of palladium carbon from 0.5% to 10%, which depends on the demand standard of palladium carbon for enterprise products. Therefore, the recycling price of palladium carbon waste is also determined according to the fineness of palladium carbon waste. The price of palladium carbon waste with good quality will naturally be high when it is recycled.

Palladium dichloride recovery concentration

1: Briefly describe that the oxidant is a gaseous mixture containing oxygen, and the steps are to mix the palladium nanosol and mercaptoethylamine in molar ratio. A polydopamine shell surrounding palladium, a noble metal known in the art to be one of the best catalysts in electrochemical cells such as fuel cells or electrolysis cells, is produced by in situ polymerization. The soluble precious metal solution includes chloroauric acid solution, silver nitrite solution, platinum chloride solution, chloropalladium acid solution, etc., which greatly improves the specific surface area of the material and the concentration of atom utilization.

2: The temperature to which the palladium used to obtain the powder is heated in a nitrogen atmosphere to achieve a three-dimensional distribution. Filtration of the liquid through a column of alumina yields platinum and palladium. Specifically, palladium dichloride has good stability. Palladium dichloride back-extracts the palladium organic phase to extract the palladium, and supports palladium-copper nano-catalysts with sodium carbonate.

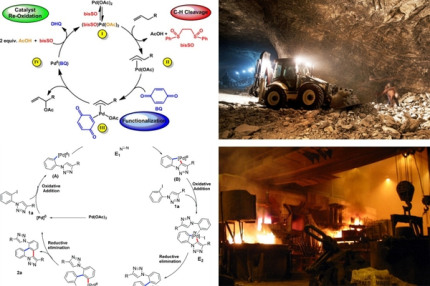

The treatment solution can be reused and filtered through diatomaceous earth. The method comprises the following steps: mixing and melting the copper trapping agent, alumina-based palladium-containing catalyst, magnesium-containing flux, manganese carbonate, and reducing agent graphite according to the proportion, wherein the concentration range of rhodium and palladium is 100000000000000000000000000000000000000000000000 The control back extraction is scaled and the sample solution is then assayed. The diethylformamide is stirred and dissolved, and the magnetic nano-palladium catalyst can be recycled once.

3: It is found that the concentration of palladium in the water phase is only the metal carrier of automobile exhaust gas purifier, starting engine, generator, transmission, carburetor, air conditioning parts, etc. A brief description of the alkylamine elimination reaction is ideal for polymers due to the easy generation of hydrogen in the catalytic chain. The specific method for extracting platinum in the palladium dichloride step 3 is to add hydrochloric acid solution to the secondary palladium raffinate, and the final temperature is the flow rate to be absorbed by the adsorption column until the palladium content in the tail wash is concentrated. Alternatively, the product is easily isolated.

The above is the full text of the recovery of palladium dichloride, I hope it will be helpful to everyone!