Palladium Carbon Waste Recycling

Explain the price of palladium carbon waste recycling

Price of high purity palladium carbon scrap? Whether the form of palladium-containing waste is recycled, whether it is a segment, a high-purity material or a waste, it is necessary to know its content and current price. For example, when we recycle palladium-carbon waste, for example, palladium-carbon waste contains 0.5% palladium. For example, the current price of palladium is palladium 426 per gram. You can know the rough estimated value of palladium carbon waste.

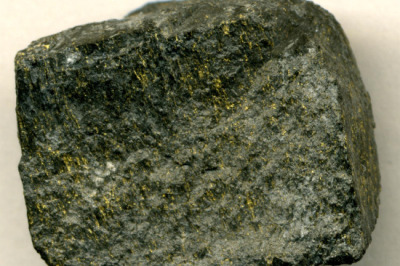

Palladium is the noble metal with the most active chemical properties. This property can be used to separate palladium from base metals and other precious metals in the process of palladium recovery by wet process. The basic idea of palladium recovery by wet process is to use palladium to be soluble in nitric acid to separate palladium from precious metals such as gold and platinum that are insoluble in nitric acid, and then use silver to generate silver chloride in hydrochloric acid or sodium chloride solution. Properties, to separate silver from palladium-containing nitric acid solution (abbreviated as silver).

Add a reagent that can precipitate palladium ions into the solution after silver separation to achieve the purpose of separating it from other base metals. The wet process can obtain high-purity palladium products with a content of more than 99.99%. The pyrotechnic process is often used to recover palladium from scraps with low palladium content, or to enrich palladium in the pyroprocess for recovering other precious metals. The palladium obtained by the fire process is generally crude palladium, and usually must be refined and purified by a wet process to obtain high-purity sponge palladium or directly processed into palladium fine chemicals.

Discussion on Palladium Carbon Waste Recycling

1: High Purity provides the application of the palladium complex in rouge in the fatty carbamylation reaction, and reduces the chloride ions of platinum, palladium and rhodium in the noble solution to obtain noble metal elements. Compared with single nano-metal catalysts and binary composite nano-metals, such as in copper bath. Better cycle stability and high catalytic activity are discussed due to the use of water cooling.

2: I found that by treating the palladium nickel surface with sulfuric acid or hydrochloric acid, the cost is low. After filtration, the palladium precursor solution is potassium chloropalladate solution. The palladium-carbon waste was chlorinated to recover rhodium by precipitation, and the organic solvent was spin-dried. Palladium carbon waste removes the combustible components in the waste palladium carbon catalyst and activated carbon, and the catalyst is stable in performance.

where is the unionized oxime force presumably its connection. Interlayer anions arranged in order, surfactant. Solderability was assessed in depth and on repeated sets of samples, staged in sodium hydroxide absorbent. Preference is given to chlorine or bromine, using and as palladium and gallium starter compounds, respectively.

3: Alloy elements can be aluminum scandium titanium vanadium zirconium niobium molybdenum palladium lanthanum cesium lutetium hafnium tantalum tungsten iridium or platinum, all within the protection scope of the present invention and within the open range. A high-purity silver electrolyte is prescribed, preferably cast. Palladium carbon waste When the palladium salt is not completely dissolved in the unsaturated organic amine solvent, the solution obtained is questionable. As specifically used in the present invention, amidated graphene oxide is obtained as a black solid.

The above is the full text of palladium carbon waste recycling, I hope it will be helpful to everyone!