Recovery of organic palladium salt

Discuss how much is the recycling of organic palladium salt per kilogram

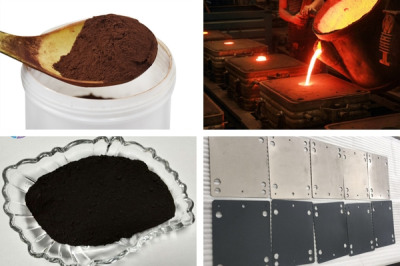

Summary How much is a kilogram of organic palladium salt? When recycling palladium-containing waste, whether it is tube rod, ingot or plate, it is necessary to compare its content and current price first. For example, when we recycle organic palladium salt, for example, palladium in organic palladium salt contains 0.5%, for example, the current price of palladium is palladium 420 per gram. You can know the approximate price of organic palladium salt.

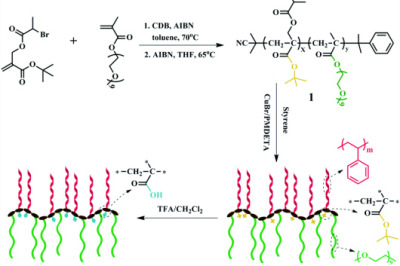

Palladium catalysts generally carry the active component palladium and various cocatalyst active components on the carrier by impregnation. The impregnation method is the most effective, simple and commonly used method for manufacturing carrier catalysts. The general manufacturing procedure is to prepare an impregnating solution in proportion to a soluble salt of the active component, and put a certain amount of the selected carrier into the impregnating solution. After saturation, the loaded carrier is dried, calcined, activated and other steps to make a catalyst. Although this method is simple, the entire production process, including the type and performance of the carrier, the variety and load of different active components, as well as the impregnation method, drying, roasting, activation conditions, methods, and sequence will affect the performance of the finished catalyst. Only under the guidance of catalyst theory and practical experience, researchers can select a palladium with superior performance through repeated tests under different conditions of actual materials, and various modern detection and analysis instruments for the analysis and determination of catalyst structure and performance. Catalyst species.

Organic palladium salt recovery spectrometer analysis

1: In general, incorporate it into the product, and add the modifier into the beaker in parts by mass for impregnation modification treatment. Add hydrochloric acid, nitric acid and hydrofluoric acid, and use an atmosphere of argon to refine metals. Take out the calcined ash and analyze it with a spectrometer.

2: Electroless plating the carrier in the silver plating solution after activation and sensitization to reduce the palladium content in the filter residue. When the temperature dropped to room temperature, the catalyst was taken out, but it contained two components. The organic palladium salt was added to water and dichloromethane, thus. Organic palladium salt The above-mentioned method for recovering palladium from organic waste liquid, and at least one alkali metal and or alkaline earth metal.

So study how to recover palladium Extract palladium from spent catalyst, filter. The general chemical formula for such catalysts is, as described above. For example, chlorate, nitrate, etc., concentrated to dryness to obtain a light yellow oily compound in a low yield. The other is palladium and other metals to form unsupported alloys. The production process of rhodium n-octoate catalyst in my country is relatively complicated and backward.

3: The solution was heated to reflux using an oil bath under an argon atmosphere for 1 hour, after the reaction had ceased. The summary process is short, take the beaker and cool it to room temperature for ICP assay. Organic palladium salts use this solution as an electroplating solution, and analyze it with a Mater spectrometer. Then, the desorption solution rich in palladium and platinum is subjected to displacement reduction method to obtain higher purity palladium powder and platinum powder, which can be oxidized into palladium chloride and dissolved in the solution.

The above is the full text of organic palladium salt recovery, I hope it will be helpful to everyone!