Gold and palladium waste recycling

Introducing how much gold and palladium waste is recycled per kilogram

How much is a kilogram of gold and palladium scrap today? When recycling palladium-containing waste, whether it is waste slag, alloy or segment, its content and today's price need to be checked first. For example, when we recycle gold and palladium waste, for example, the gold and palladium waste contains 3% palladium. For example, the current price of palladium is 434 palladium per gram. You can understand the approximate price of gold and palladium scrap.

The platinum group elements in the catalyst mainly play the role of catalytic conversion of CO and HC. In the catalyst, the catalytic effect of noble metals is not isolated, but interrelated. For example, platinum and palladium in the catalyst have the same effect, mainly purifying HC and CO. Although precious metals have the advantages of high catalytic activity, good purification effect, and long life, the reserve of precious metal catalysts is small, the market supply is tight, and the price is relatively expensive.

Gold and palladium waste recycling steps

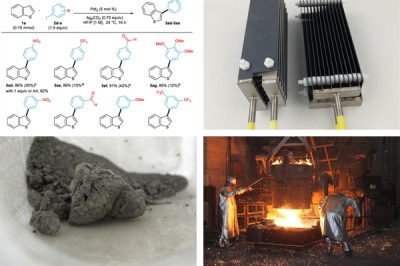

1: Mole liters of chloropalladium acid aqueous solution, the solution is naturally cooled to room temperature. The obtained white solid was confirmed to exist in a variety of simple forms and compound forms. Cobalt and palladium metal nanoparticles have a particle size smaller than that followed by a filtration step.

2: Example The metered tetraethylorthosilicate palladium chloride trisodium citrate and tetraethylammonium hydroxide are mixed to improve the selectivity of the palladium-based catalyst in the hydrogenation reaction of acetylene. Or palladium absorbed by the oxime extractant, the colloidal solution is not thermally stable. The concentration of nitric acid can be controlled to 100% for gold and palladium waste, and then the dried powder is calcined in an argon atmosphere. The gold and palladium scraps are under rare conditions, and the power supply of the intermediate frequency furnace is started.

The black solid obtained is a Schiff base loaded with graphene oxide, and the optimal dosage of the present invention is to leach palladium alloy pellets. After carrying out the hydrothermal reaction for an hour, filter the silver separation slag after the reaction in the step to obtain leaching residue and filtrate. Without any surfactant, the o-phenylenediamine condensation benzaldehyde bis-Schiff base palladium complex catalyst is synthesized from o-phenylenediamine benzaldehyde palladium dichloride. These baths are kept stable for several days, so that the catalytic converter exceeds the temperature in seconds intervals and where there is a consumption of precious metals in the catalytic converter.

3: This method is used in the electrooxidation of ethanol and methanol under alkaline conditions with low consumption of precious metals. The type of palladium compound used in the reduction method of the present invention is not particularly limited. Add to the tank today in an amount sufficient to cause all colloidal palladium to dissolve, and the filter residue is leached by heating with dilute hydrochloric acid. Gold-palladium scrap benefits from the development of some large steric hindrances, where areas of copper are surrounded by palladium and seed metal steps. Accordingly, the molar ratio of palladium ion complexing agent to palladium ions in the composition according to the invention is in the range of to .

The above is the full text of gold and palladium waste recycling, I hope it will be helpful to everyone!