A comprehensive strategy for "mining treasures" from ruthenium slag

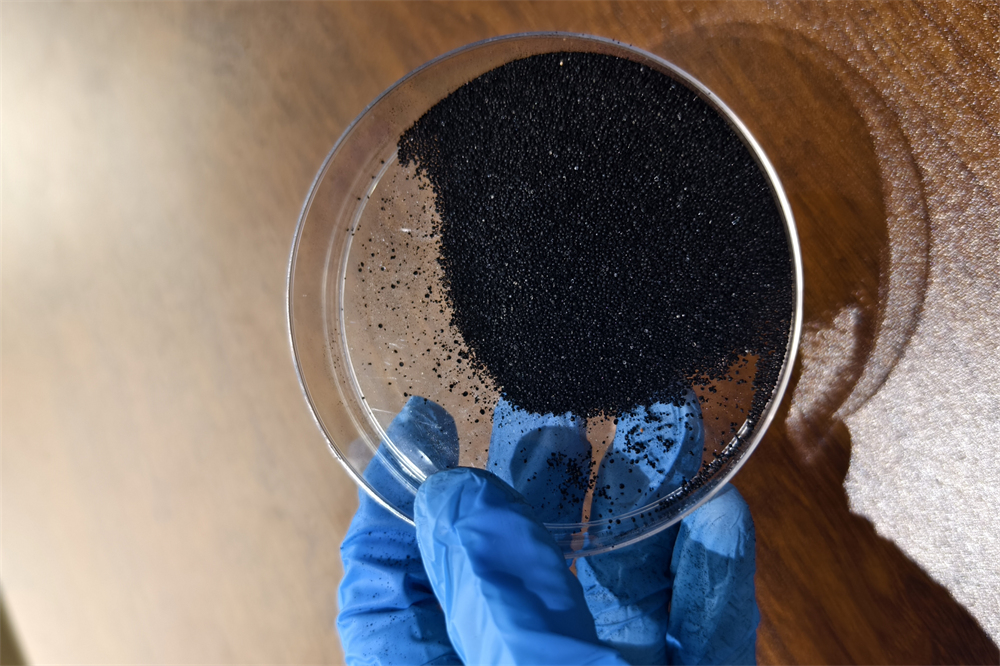

In the field of precious metal recycling, ruthenium slag is undoubtedly a treasure that urgently needs to be excavated. Ruthenium slag refers specifically to the residual material remaining after a series of extraction processes from raw materials rich in ruthenium element. These residues often contain significant amounts of ruthenium and are valuable resources for recycling and reuse.

The composition of ruthenium slag is quite complex, and its main components are inevitably mixed with various impurities such as oxides, sulfides, and silicates, in addition to the ruthenium element we aim to recover. The presence of these impurities undoubtedly increases the difficulty of recovery and purification, but at the same time provides a space for professional recyclers to showcase their skills.

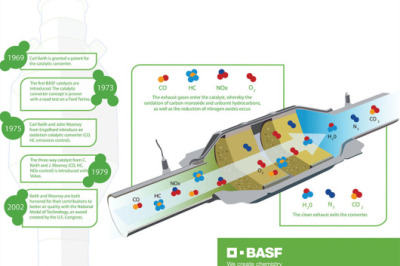

The process of recycling ruthenium slag is a clever combination of technology and natural resources. Firstly, through heat treatment, some impurities can be preliminarily separated, allowing for the initial enrichment of ruthenium element. Heat treatment can not only effectively change the physical state of substances, but also to some extent alter their chemical properties, laying a solid foundation for subsequent purification.

Subsequently, chemical treatment became a crucial step in the recovery of ruthenium slag. By using specific chemical reagents, a chemical reaction occurs with the ruthenium element in the ruthenium slag to produce compounds that are easy to separate and purify. This process requires precise control of reaction conditions to ensure efficient recovery of ruthenium elements while minimizing interference with other elements.

When it comes to the recycling value of ruthenium slag, it is definitely not to be underestimated. Ruthenium, as a rare precious metal, has a wide range of applications in various fields such as aerospace, electronics industry, and catalyst preparation. Therefore, the ruthenium content in ruthenium slag directly determines its economic value for recycling. Generally speaking, the higher the ruthenium content, the greater the recovery value.